Sticking to the composites industry leader

Automated Terminal of ShanghaiYangshan Port

Located on the deep sea port area of Shanghai Ocean Mountain outside the mouth of Hangzhou Bay, it is composed of dozens of islands such as Dayangshan and Xiaoyangshan. It is the first port in China to be built on an island. Yangshan Port is about 32 kilometers northwest of Shanghai's Nanhui Luchao Port and about 90 kilometers south of Ningbo Beilun Port. It is only 45 nautical miles away from international routes. It is the closest deep-water port to Shanghai and has become a new coordinate for Shanghai International Shipping Center.

Category:

Road&Bridge

Consult

DESCRIPTION

Located on the deep sea port area of Shanghai Ocean Mountain outside the mouth of Hangzhou Bay, it is composed of dozens of islands such as Dayangshan and Xiaoyangshan. It is the first port in China to be built on an island. Yangshan Port is about 32 kilometers northwest of Shanghai's Nanhui Luchao Port and about 90 kilometers south of Ningbo Beilun Port. It is only 45 nautical miles away from international routes. It is the closest deep-water port to Shanghai and has become a new coordinate for Shanghai International Shipping Center.

The total land area of Yangshan Gangshan Phase IV is 2.23 million square meters, and the natural water depth at the front of the terminal is mostly 11 to 15 meters. Yangshan Phase 4 has a total of 7 container berths and a total length of 2,350 meters. The design annual capacity is 4 million TEUs in the early stage and 6.3 million TEUs in the long term. Looking at the world, it is unprecedented for such a large-scale automated terminal to be built and put into operation at one time.

After the container ship is docked, the automatic loading and unloading bridge crane lifts the container to the transfer platform, and then the other side-side trolley is lifted to the automatic guided vehicle. Set the line to travel to the designated box area, then lift the container to the guide vehicle bracket, and finally lift the container into the box area by an automated track crane. The entire loading and unloading process is unmanned, and managers can monitor the entire process in the central control tower.

Compared with the traditional container terminal in the past, the biggest difference between the Yangshan Phase 4 automated terminal and the traditional container terminal lies in the innovation of the loading and unloading process, which brings new problems to the civil construction.

The terminal needs a lot of magnetic nails to locate the automated trolley. If the conventional reinforced concrete structure is cast, there will be interference. The China Aviation Industry and Civil Aviation Administration designed to use glass fiber bars to replace the steel bars, so there is basically no interference.

In addition, the project also widely used products such as composite fences, power transmission rods, etc., effectively avoiding the impact of steel corrosion on the engineering life.

Project Application Type: Coastal Engineering-Civil Engineering Composite Material Reinforcement, Guardrail, Power Transmission Bar Application

characteristic:

Corrosion resistant and non-magnetic

customer satisfaction:

satisfaction

FRP bars are used in the pavement of heavy-duty concrete pavements in the port area. They are corrosion-resistant and have no electromagnetic interference, which facilitates automatic signal transmission.

Fiber-reinforced composite material transmission rod is made of high-performance resin and high-strength fiber through pultrusion process, which can replace the original steel material transmission rod. Features: corrosion resistance, high tensile strength, good shear resistance, magnetic permeability insulation.

Composite refrigerated box bracket, frame structure column and beam adopt continuous production FRP shell, internal structure is built-in hollow square tube with paulownia core.

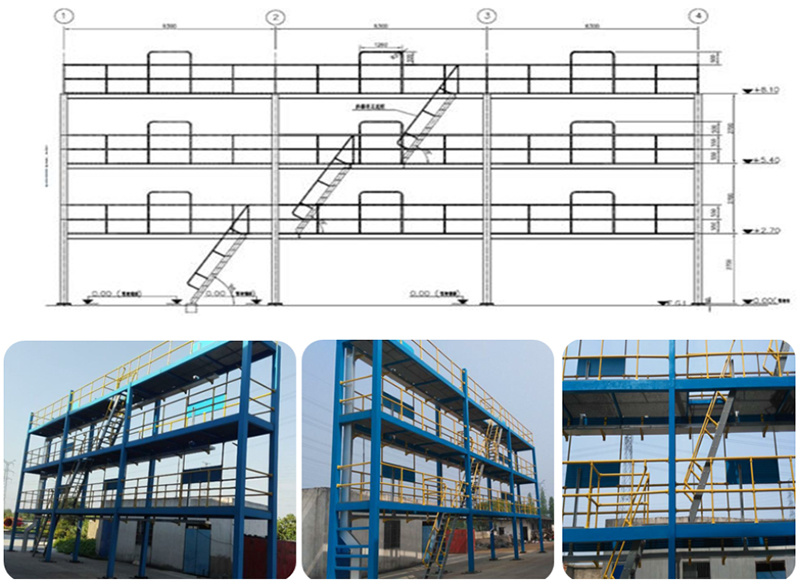

The platform aisle board adopts composite material molding grid board (size 38 * 38 * 38). The design load of the grille plate is 4kN / ㎡, and the grille plate and the beam longitudinal beam are fixed by stainless steel clips, which has a high bearing capacity and is safe and lightweight.

The guardrail and handrail are made of composite material chrome yellow round pipe (specification: Φ50mm * 5mm), the height is 1.1m, and the longitudinal distance is not more than 1.1m according to the design requirements. The railing installation and connection parts are all composite tees, crosses, elbows, and bases.